Here’s a truth many commercial property owners may not always admit out loud: getting a commercial roof cost estimate often feels like signing a check while wearing a blindfold – and hoping the final number doesn’t come back higher than expected!

If you’ve ever felt hesitant or uncertain during bidding, you’re not alone. We’ve worked with clients who initially came to us feeling wary after past experiences. But here’s the good news: roofing doesn’t have to work that way. With the right partner, the process becomes clearer, more predictable, and much more controlled on your terms.

That’s what Silicoat Roofing provides: clarity, structure, accountability, and most importantly, cost transparency at every stage of the project.

Stay with us. In the next sections, we’ll walk step-by-step through how a proper estimate is formed, how to spot red flags in pricing, and how the right contractor can eliminate uncertainty from the process.

Building-Side Variables That Drive the Estimate

Every commercial roof cost estimate begins with the same simple question: what are we building on top of? For many clients, this is where confusion begins, because one roof might look like another, but the underlying conditions can vary dramatically.

Existing roof condition

A roof that appears stable from above may be hiding deeper issues beneath the membrane, especially if insulation has absorbed moisture or the substrate is weakening. When that’s the case, the project requires additional removal, replacement, and disposal work, far beyond a simple membrane swap. This stage of evaluation is often when clients gain clarity about their roof’s true state, and it’s also where we catch issues early enough to prevent costly surprises later.

Roof size and access conditions

Two roofs with the same square footage can still represent completely different logistical realities. A 50,000-square-foot rooftop in an open industrial setting is pretty straightforward. But the same size roof in a dense downtown area, surrounded by pedestrian pathways, adjacent windows, and truck restrictions, is a different challenge entirely. Access also matters vertically: a three-story lift is not the same as a fifteen-story haul. The easier the access, the more efficient the labor and staging.

Structural load and code requirements

Local regulations, climate expectations, and structural engineering standards all play a role in calculating what the roof can and must support. Certain projects require increased insulation thickness, vapor barriers, or adjustments to slope to ensure proper water drainage. These details aren’t discretionary – they’re essential for compliance and longevity. Accounting for them early helps ensure the estimate reflects the real installation requirements.

Obstructions, penetrations, and equipment

Commercial roofs rarely present a clean, empty working surface. Instead, they may host HVAC units, vent stacks, skylights, exhaust systems, mechanical mounts, electrical conduits, or telecom equipment. Every penetration creates a waterproofing challenge that requires custom flashing, sealing, and detailing. The more equipment on the roof, the more time and precision required.

Once the physical environment is clearly understood, the next step is choosing the right roofing material – one that matches the building’s function and climate exposure.

Different Materials and How They Influence Project Pricing

Most commercial roofs don’t need the “most expensive” system – they need the right one. Let’s explore the most common materials:

TPO

Energy-efficient and highly reflective, TPO’s white surface helps reduce heat absorption and lower HVAC demand inside the building. This is especially beneficial for climates with prolonged sun exposure or facilities that run cooling systems heavily. Many owners appreciate that TPO sits in the mid-range for material cost (not the cheapest, not the most expensive), but with a strong performance-to-value ratio. It’s a system that balances durability, sustainability, and operating cost savings over time.

PVC

PVC is the specialist material – and there’s a reason it’s preferred for restaurants, manufacturing facilities, and buildings that emit oils, exhausts, or chemical particulates. Unlike other membranes, commercial PVC roofing systems resist grease penetration and chemical breakdown. Yes, the upfront material cost is higher, but it pays off in environments where rooftop contamination is likely. If a facility expects airborne grease, solvent exposure, or chemical vapors, PVC is the smart choice, not a luxury pick.

EPDM

For very large roofing footprints or colder regions, EPDM often becomes the most economical solution. It’s a durable rubber membrane that stays flexible in freezing conditions and has a reliable performance history. It is not reflective, so it’s not ideal for high-solar-gain environments expecting cooling savings, but for many warehouses or industrial spaces in cooler climates, EPDM delivers strong longevity at an attractive cost-per-square-foot.

Modified Bitumen

This is a trusted workhorse in the commercial roofing world, particularly for older structures or phased retrofit projects. Modified bitumen combines asphalt-based durability with layered application control, offering proven waterproofing reliability. It may not be the “modern-sounding” membrane that gets attention, but it has decades of real-world performance behind it. For buildings with existing bitumen roofs, it can also streamline tie-ins and transitions.

In many cases, the smartest decision is not the “trendiest” option, but the one that complements the building’s usage and budget strategy.

The Labor and Logistics Story Behind Your Estimate

Materials influence pricing, but labor often tells the real story, because roofing isn’t just about what goes onto the building, but how it gets there and who installs it.

Tear-off vs overlay

A full tear-off means removing every layer of the existing system: membrane, insulation, fasteners, adhesives. That involves dumpsters, hauling, landfill fees, labor hours, and additional staging steps. An overlay, however, can dramatically reduce both cost and disruption by installing a new system over the existing one. But it is only appropriate when the underlying layers are structurally sound and moisture conditions are verified. We never recommend an overlay unless testing proves it’s safe.

Crew expertise

There’s a measurable difference between a job done by general laborers and one led by experienced roofing specialists. At Silicoat Roofing, crew leads understand seam welding, fastening density requirements, edge termination, wind uplift constraints, drainage patterns, and thermal movement behavior. This prevents small installation mistakes that later cause membrane shrinkage, seam failure, or pooling.

Delivery methods

Logistics matter. If the site allows materials to be lifted by crane directly onto the roof, labor is streamlined. If roads are tight or the building is unusually tall, workers may need to carry materials up stairwells or elevators in incremental loads. That increases time and cost. We evaluate these conditions early so the estimate reflects reality rather than best-case assumptions.

Understanding the roof is one part of budgeting. Understanding the estimate paperwork is another – and that’s where cost clarity can be won or lost.

How to Read a Roofing Bid and Spot Hidden Costs

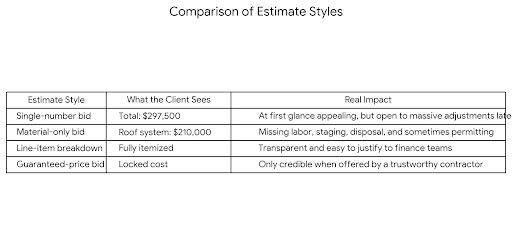

Here’s a simple truth: vague estimates lead to expensive surprises. Clear ones prevent them.

We help clients compare bids apples-to-apples. Many discover that the “cheapest” price isn’t actually the cheapest project – it’s simply the least disclosed.

Preventing Cost Overruns Before They Happen

Cost escalation rarely comes from unforeseeable events. More often, it comes from incomplete planning.

Pre-bid inspection

We don’t guess. We verify. And that means actually getting eyes (and sometimes instruments) on the roof. A good estimate starts with understanding how the existing roof system is layered, whether the membrane is nearing failure, how seams were previously installed, and whether flashing points are intact or compromised. For many clients, this is the moment when they learn more about their roof in 30 minutes than they had in 10 years of occupancy.

Core sampling

Moisture-ridden insulation isn’t always visible, but it’s financially significant. A roof can look structurally fine from above, yet have saturated insulation beneath the membrane. That trapped moisture changes the weight load calculations, influences disposal requirements, and may require full tear-off instead of repair and maintanance. This step alone has saved some of our clients tens of thousands of dollars in surprise adjustments.

Clear scope definition

If something changes, you have hear it immediately, not at the final invoice meeting. During a roofing project, conditions sometimes reveal unexpected realities: a deteriorated parapet, hidden decking damage, or unsealed penetrations from previous work. The difference between a reputable contractor and a frustrating one is communication timing. We explain discoveries as they arise, outline the options, get approval, and adjust collaboratively, so our clients never learn about changes after the fact. We know that surprises can feel like ambushes, and that’s not how we work.

“Property owners don’t just need a new roof. They need confidence in the budgeting process, clarity in communication, and peace of mind that there won’t be surprises halfway through. Our responsibility is bigger than installation – it’s about protecting your financial decision.” – Rick Dodaj, Founder of Silicoat Roofing.

Common Questions About Commercial Roof Cost Estimates

How do I ensure the estimate is accurate?

Request a detailed breakdown and verification of moisture conditions through core sampling.

Should I always choose the material with the longest lifespan?

Select the material that best fits your building usage rather than chasing a theoretical maximum lifespan.

Can overlays really save money?

Yes – when used correctly. They reduce tear-off and disposal costs, but we never recommend an overlay unless testing proves it’s safe.

How long does a commercial roof replacement typically take?

Timeframes vary by building size, staging, and weather. A few days to a few weeks is typical, but we can give you a more accurate estimate ater an analysis.

Build Your Roofing Budget With Confidence

Replacing a commercial roof is one of the biggest investments a building owner will ever make. When you understand how pricing works, what contractors should (and shouldn’t) include in a proposal, and how to compare bids fairly, you’re no longer at the mercy of vague estimates or surprise change orders. You’re in control.

A solid commercial roof cost estimate isn’t just about numbers. It’s about transparency, long-term planning, and choosing a partner who protects your building like it’s their own. That’s the difference Silicoat Roofing brings to every project. Our team helps you cut through industry noise, evaluate your options clearly, and make decisions that strengthen your property for the next decade, not just the next rainy season.

If you want clearer pricing, smarter planning, and a roofing partner that puts accuracy first, we’re here to help. Contact us today to understand your options and make the best decision for your building and your budget.

About the Author

Rick Dodaj is the founder and CEO of Silicoat Roofing, specializing in commercial roofing solutions that protect businesses and their investments. With extensive experience in commercial roofing, Rick leads a team dedicated to providing cost-effective, long-lasting roofing solutions. Connect with him on LinkedIn to learn more about commercial roof maintenance and protection strategies.

Previous Post

Previous Post Next Post

Next Post