For many Detroit building owners, roofing decisions aren’t just about materials: they’re actually about peace of mind. After all, you’re managing budgets, tenants, and operations – the last thing you want is a roof system that fails prematurely or drains your maintenance budget year after year.

That’s why the debate between modified bitumen roofing and built-up roofing (BUR) matters so much. Both have earned reputations as reliable, time-tested asphalt roofing systems for low-slope commercial roofs, but they perform differently under Detroit’s weather patterns, where freezing winters and hot summers push roofing materials to their limits.

Understanding these systems is the first step to choosing the one that will deliver the best long-term protection and value. At Silicoat Roofing, we’ve helped hundreds of commercial facilities make that choice with confidence. If you’re unsure which system fits your property, this guide breaks it all down so you can plan smart, not just patch problems later.

Understanding Modified Bitumen Roofing

Modified bitumen (MB) roofing was developed as a modern improvement over traditional BUR systems. It blends asphalt with polymer modifiers, typically SBS (styrene-butadiene-styrene) or APP (atactic polypropylene). The result is a flexible, durable membrane designed to resist temperature swings and stress from building movement.

How It’s Built

These systems are installed in multiple layers (a base sheet, reinforcement mat, and cap sheet) adhered with heat, cold-applied adhesives, or self-adhering technology. Each layer works to enhance weather resistance, flexibility, and UV resistance.

For many Detroit facilities, flexibility is key. Roofs expand in summer and contract in winter, and a rigid surface can crack under that stress. Modified bitumen accommodates that movement, making it a top choice for buildings exposed to thermal cycling.

Advantages of Modified Bitumen Roofing

- Durability in Harsh Weather: The polymer blend helps resist cracking and brittleness during freeze-thaw cycles.

- Ease of Maintenance: Repairs can be localized and straightforward, which is ideal for busy facilities with ongoing operations.

- Energy Efficiency Options: Reflective cap sheets can reduce heat absorption, lowering cooling costs.

- Variety of Installation Methods: Torch-applied, cold-applied, and peel-and-stick systems allow flexibility based on site conditions and safety regulations.

For many facility managers, the draw of modified bitumen is its balance of modern materials with a proven asphalt foundation.

Challenges to Consider

No system is perfect. Modified bitumen roofing requires precise installation temperatures and experienced crews to ensure proper adhesion, as poor workmanship can lead to seam failures or trapped moisture.

That’s where working with a seasoned contractor pays off. For instance, we use strict quality control and heat monitoring during application to ensure a consistent bond across every seam.

Built-Up Roofing (BUR): The Classic Performer

Before modified bitumen came along, built-up roofing (BUR) was the standard for commercial low-slope roofs. It’s sometimes called the “tar and gravel” roof because of its composition: multiple plies of roofing felt set in hot asphalt, topped with gravel or reflective coatings for protection.

How It’s Built

BUR systems typically use three to five alternating layers of bitumen and reinforcing fabric, forming a dense waterproof membrane. The surface can be finished with gravel, mineral cap sheets, or reflective coatings depending on performance needs.

Advantages of BUR Systems

- Proven Track Record: Decades of successful installations across commercial buildings worldwide.

- Exceptional Waterproofing: Multiple layers prevent water damage: if one layer fails, others still protect.

- UV and Impact Resistance: Gravel or mineral surfaces shield the membrane from sun and physical damage.

- Cost-Effective for Large Roofs: When installed efficiently, BUR can offer excellent long-term value for expansive surfaces.

Challenges to Consider

BUR systems are heavy, requiring adequate structural support. The installation involves hot asphalt, which can generate strong odors and disrupt on-site operations. They also demand skilled crews with safety protocols in place for heating equipment.

However, many Detroit industrial facilities still prefer BUR for its ruggedness. It’s a system that has stood up to decades of snow, ice, and rooftop traffic – and continues to perform when installed by experts.

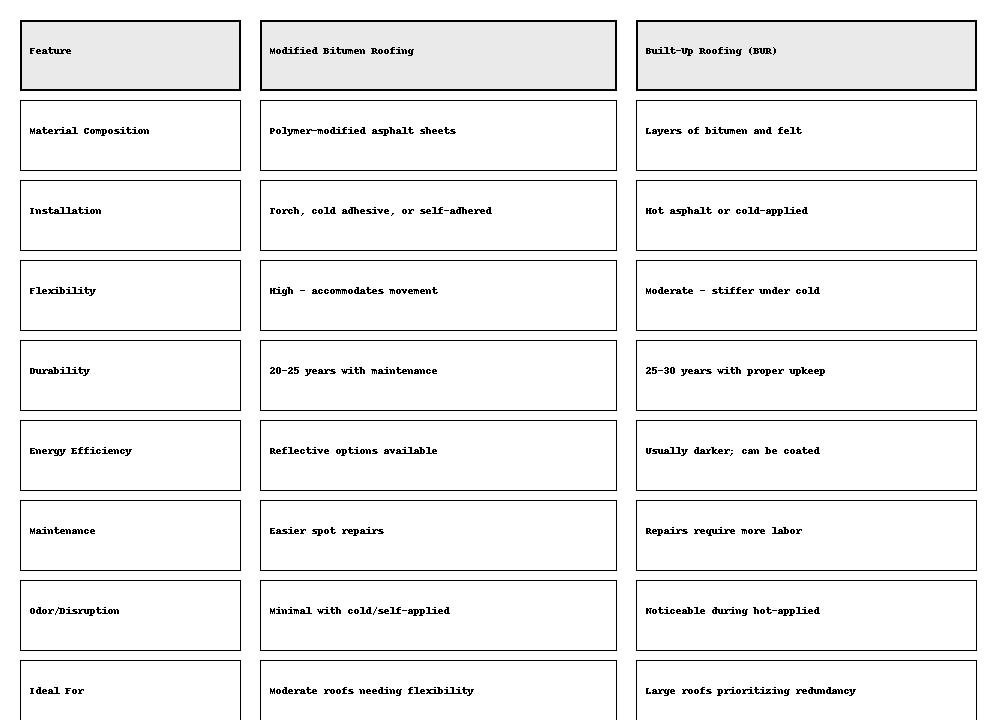

Modified Bitumen vs BUR: Side-by-Side Comparison

Below is a simplified overview for facility managers weighing both options:

How Detroit’s Climate Influences Roof Choice

Detroit’s climate tells a story every facility manager knows: freezing winters, heavy snow loads, and summers that swing from humid to hot. Those conditions can make or break an asphalt roofing system.

Cold Weather Performance

Modified bitumen’s polymer structure allows it to stay pliable in low temperatures, reducing cracking risks. On the ohter hand, BUR’s rigidity, while advantageous for load-bearing, can be more prone to thermal stress unless properly maintained.

Moisture and Snow Load

Both systems handle water well when installed correctly. BUR’s multi-layer design offers redundancy, which ideal for roofs with standing snow or occasional ponding. Modified bitumen, with strong seams and reflective cap sheets, resists leaks but relies more on consistent maintenance.

Heat and UV Exposure

In Detroit’s summer months, UV radiation can accelerate aging. Reflective cap sheets on modified bitumen systems help mitigate heat absorption, while BUR roofs often benefit from reflective coatings applied post-installation.

In short: the right system depends on your building’s priorities. For flexible, quick-install solutions, modified bitumen excels. For facilities needing heavy-duty, long-term redundancy, BUR remains a top performer.

“Choosing between modified bitumen and BUR is about how your roof supports the way you do business. Before recommending a system, we look at every factor: foot traffic, drainage, insulation. That’s how you build roofs that perform for decades, not just years.” – Rick Dodaj, Founder of Silicoat Roofing.

This philosophy guides every Silicoat project. Our team conducts full-site evaluations to understand load capacity, drainage, and repair history before suggesting the ideal roofing solution. That detailed approach ensures the system you choose meets the demands of your operations, season after season.

Maintenance and Lifecycle Planning

Every roof system, regardless of type, demands care. What separates average performance from exceptional longevity is a proactive maintenance plan.

Routine Inspections

Twice-yearly inspections, typically in spring and fall, help catch seam splits, blisters, or surface wear before they escalate. Silicoat technicians check flashing, penetrations, and drainage systems to prevent leaks during freeze-thaw cycles.

Surface Care

Modified bitumen roofs benefit from keeping reflective coatings clean and intact. BUR roofs need gravel redistribution and occasional top-coat renewal to maintain UV protection.

Repair Strategies

Modified bitumen repairs often involve heat-welded patches, while BUR systems may require removing and replacing layers. Both benefit from certified crews familiar with asphalt-based materials.

Roof maintenance can exceed its expected lifespan by 20–30%. Our programs help Detroit facilities plan budgets, minimize unplanned downtime, and extend system life with predictive care instead of reactive fixes.

Energy and Sustainability Factors

With rising energy costs, more property managers are factoring sustainability into roof selection.

Modified bitumen systems now come in cool-roof formulations with reflective granules, improving energy performance and meeting green building standards. BUR roofs, while traditionally darker, can achieve similar results with white or aluminum coatings.

The takeaway is that sustainability isn’t limited to new materials, it’s about how the system is designed, installed, and maintained.

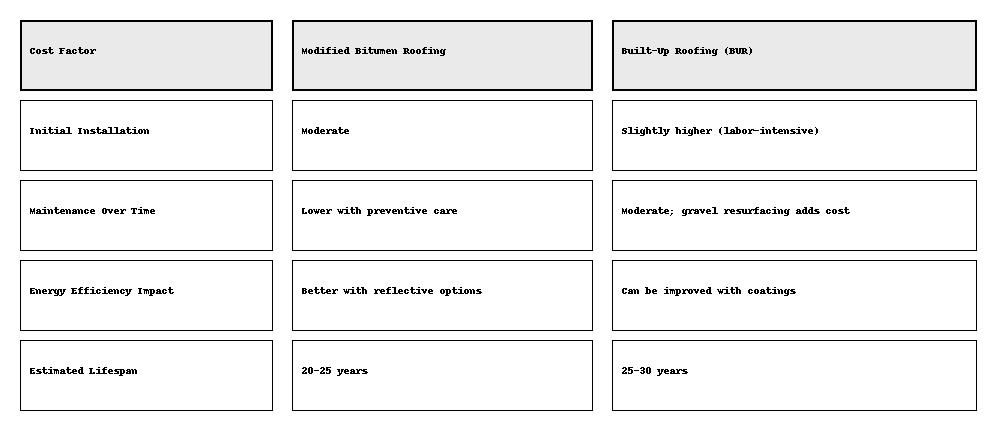

Cost Considerations

We understand that upfront cost is often the first question. But true value lies in lifecycle cost—the total spent on installation, maintenance, energy, and eventual replacement.

Silicoat Roofing helps clients run cost-benefit analyses before installation, showing not just what you’ll spend—but what you’ll save in avoided repairs and energy over time.

How Silicoat Roofing Supports Detroit Facilities

Choosing a roofing system is only part of the process—executing it right is where results happen. We deliver turnkey commercial roofing services across Detroit, from inspections and replacements to silicone coatings that rejuvenate aging asphalt roofs.

Silicoat Roofing specializes in:

- Full roof evaluations and infrared moisture scans.

- Certified modified bitumen and BUR installations.

- Seamless silicone coating systems for long-term waterproofing.

- Maintenance plans tailored to facility budgets.

When you partner with Silicoat, you’re guided by experts who have seen what works across Michigan’s toughest conditions.

Common Questions About Modified Bitumen and BUR Roofing

Which roofing system lasts longer: modified bitumen or BUR?

BUR systems often last slightly longer (up to 30 years) due to multiple layers of redundancy, while modified bitumen averages 20–25 years. Proper maintenance can extend either system’s life significantly.

Is modified bitumen better for small buildings?

Yes. Modified bitumen is ideal for smaller to mid-size commercial roofs where flexibility, ease of repair, and faster installation matter.

How often should commercial asphalt roofs be inspected?

At least twice a year and after major storms. Preventive inspections can prevent minor seam issues from turning into leaks or insulation damage.

Can silicone coatings be applied over both systems?

Absolutely. Silicoat Roofing specializes in silicone restoration membranes for both modified bitumen and BUR roofs, extending lifespan without full replacement.

What’s the best roofing choice for Detroit’s climate?

For most Detroit facilities, modified bitumen offers the flexibility needed to handle temperature swings, while BUR suits heavier industrial roofs needing extra redundancy. The ideal system depends on your building’s structure and operational needs.

Build Smart, Build to Last

Both modified bitumen roofing and built-up roofing (BUR) have stood the test of time for low-slope commercial roofs. The right system depends on how your facility operates, how much disruption you can tolerate during installation, and how you plan for long-term maintenance.

In Detroit’s demanding climate, roofing isn’t a “set it and forget it” investment: it’s a strategy.

And when that strategy is guided by Silicoat Roofing, you gain more than a watertight surface. You gain a partner focused on performance, cost control, and lasting protection.

Contact us today for a free roof evaluation and discover which asphalt system best fits your facility’s needs.

About the Author

Rick Dodaj is the founder and CEO of Silicoat Roofing, specializing in commercial roofing solutions that protect businesses and their investments. With extensive experience in commercial roofing, Rick leads a team dedicated to providing cost-effective, long-lasting roofing solutions. Connect with him on LinkedIn to learn more about commercial roof maintenance and protection strategies.

Previous Post

Previous Post Next Post

Next Post