Protect Your Commercial Roof from Harsh UV Damage

The sun can be brutal not just on your skin, but on your commercial roof. If you manage or maintain a commercial property, you’ve probably seen firsthand how relentless UV exposure can damage roofing materials over time. Cracking, fading, and premature aging aren’t just cosmetic concerns they can reduce energy efficiency, shorten roof lifespan, and even affect tenant satisfaction.

The good news? UV-resistant roof coatings are engineered to protect against exactly these threats. But choosing the right coating isn’t as simple as picking the shiniest, most reflective product on the shelf. It means understanding how different coating materials work, knowing what your building truly needs, and partnering with a roofing expert who can apply it correctly for lasting results.

“We’ve seen buildings extend roof lifespan by up to 20 years with the right coating strategy. That’s smart asset management and real savings!” – Rick Dodaj, Founder of Silicoat Roofing

Want to see how the right roof coating can protect your building, reduce cooling costs, and improve performance in extreme conditions? Keep reading to discover the best materials, application methods, and selection tips to future-proof your commercial roof.

What Makes a Commercial Roof Truly UV-Ready?

Many commercial property managers have heard terms like “cool roofs” or “reflective roof coatings” but not all roofing systems are built to the same standard. In fact, reflective roofing materials can vary greatly in performance.

To ensure your roof can truly withstand the sun’s harshest effects, here are the four key factors to evaluate before choosing a UV-protective coating:

1) Solar Reflectance Index (SRI)

The Solar Reflectance Index measures how well a surface reflects solar heat. The higher the SRI rating, the cooler your roof remains, reducing heat absorption, lowering HVAC strain, and extending the lifespan of roofing materials.

According to the U.S. Department of Energy, a properly designed cool roof can be more than 50 °F cooler than a traditional roof significantly improving a building’s energy performance.

2) Thermal-Cycling Durability

Commercial roofs naturally expand and contract as temperatures rise during the day and fall at night especially in climates with extreme temperature swings. This process, known as thermal cycling, can lead to cracking and delamination if the coating lacks flexibility.

Silicoat silicone systems are engineered to stay pliable, maintaining adhesion and performance even under the most extreme daily temperature changes.

3) Resistance to Ponding Water

Flat and low-slope commercial roofs are prone to ponding water, which can silently damage a roof. Under prolonged sun exposure, trapped water can cause coatings to degrade, peel, or blister.

Effective UV-protective coatings must be formulated to resist both moisture damage and UV stress, ensuring long-term protection for your investment.

4) Customized Roof Coating System Design

No two commercial buildings are the same. A one-size-fits-all roofing approach often leads to poor performance and wasted investment.

At Silicoat Roofing, we design customized coating systems based on each property’s local climate, building height, foot traffic, and drainage patterns ensuring maximum durability and UV resistance from day one.

Pro Tip: Selecting the right coating product is only half the battle. Proper evaluation, expert application, and consistent maintenance are critical to ensuring your roof performs as intended for years to come.

3 Steps to Achieving Long-Term Roof Protection

Protecting your commercial roof from UV degradation takes more than a quick, surface-level fix. At Silicoat Roofing, we treat every project as a system-wide upgrade, tailored to the building’s condition, operational demands, and long-term performance goals.

Here’s our proven three-step strategy that ensures every UV-resistant roof coating delivers lasting durability, energy savings, and value.

1) Evaluate and Diagnose Your Roof’s Condition

Every successful roofing project starts with a comprehensive inspection. We assess your roof’s age, UV exposure levels, and any existing signs of damage. This includes:

- Infrared moisture scans to detect hidden leaks

- Slope evaluation to identify drainage issues

- Drainage analysis to prevent water pooling problems

By the end of this stage, you’ll have a clear picture of your roof’s health and exactly what it needs for maximum UV protection and durability.

2) Design and Deliver a Customized UV-Resistant System

No two commercial buildings are the same. Once we understand your roof’s profile, we design a tailored coating system that accounts for:

- UV resistance and reflectivity

- Foot traffic and mechanical wear

- Insulation performance

- Local weather patterns and environmental impact

This ensures your roof is protected not only from UV rays but from all the factors that influence roof lifespan and commercial building performance.

3) Maintain Performance with Proactive Care

UV protection isn’t a one-time service, it’s a commitment. Our proactive maintenance plans include:

- Scheduled inspections

- Touch-ups and recoating where needed

- Full warranty support

This long-term approach ensures your roof coating continues performing at its best protecting your investment well beyond installation.

Building Function and Coating Strategy

While climate is a major factor in coating performance, how your building operates day to day plays an equally important role. Different facilities place different demands on their roofing systems here’s how we match UV-resistant solutions to specific building functions:

Distribution Centers & Warehouses

Require coatings with high solar reflectivity to maintain stable indoor temperatures and reduce HVAC strain especially for temperature-sensitive goods.

Medical Facilities & Data Centers

Need coatings with proven longevity and extended warranties, as even small temperature fluctuations can impact safety or operations. Seamless installation with minimal downtime is critical.

Manufacturing Plants & Industrial Buildings

Face vibration from machinery, exposure to exhaust/chemicals, and regular maintenance traffic. These roofs need durable, abrasion-resistant coatings that can handle physical wear and long-term UV exposure.At Silicoat Roofing, we design smarter, more resilient coating systems that work with your building’s real-world demands, not against them. And before making your final decision, it’s worth evaluating the financial ROI of UV-resistant roof coatings, as they can significantly reduce operational costs over time.

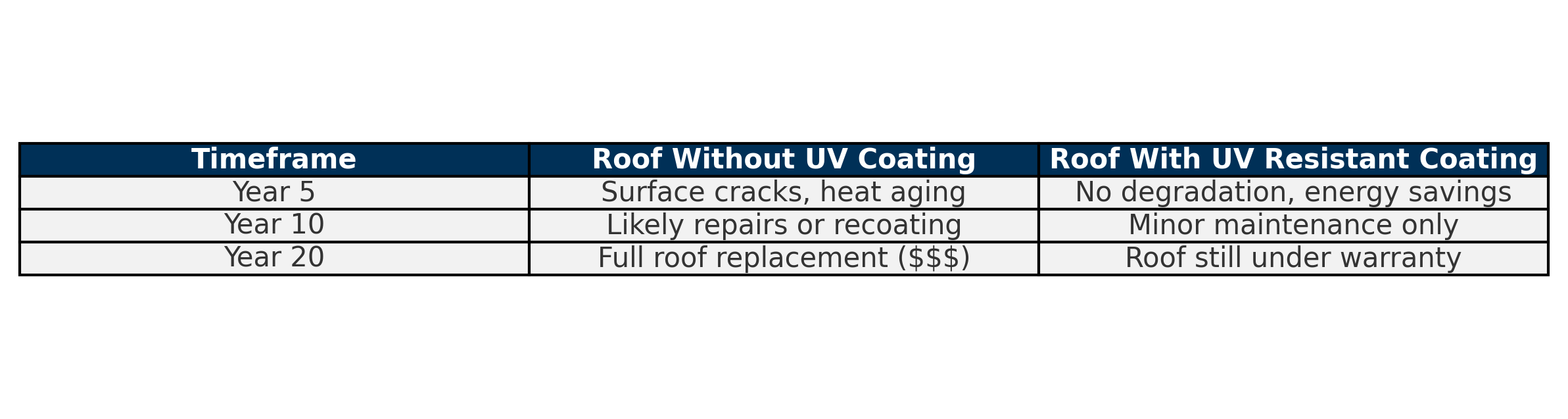

Smart Budgeting: ROI in 5, 10, and 20 Years

When facility managers and commercial building owners ask, “Is it worth the upfront cost?” We understand the hesitation. Budgets are tight, and roofing projects often compete with other priorities. But UV-resistant roof coatings aren’t just an expense; they’re a long-term investment with measurable returns.

Instead of patch repairs or short-term fixes, these coatings deliver sustained savings by lowering energy use, deferring expensive replacements, and improving operational stability. When you evaluate them over decades, the numbers tell a compelling story.

Year 5: Fast Energy Savings and Performance Boost

Within just a few years, uncoated roofs can show signs of UV damage cracking, fading, and material fatigue. These early issues increase cooling demands and often lead to patch repair costs.

With Silicoat Roofing’s UV-resistant roof coatings, degradation is stopped before it starts. Many of our clients see a 10–20% reduction in cooling costs in the first few years, thanks to higher solar reflectivity and improved thermal insulation.

Year 10: Stability with Minimal Maintenance

Around the 10-year mark, uncoated roofs typically require sealing, recoating, or other expensive interventions. These repairs are often disruptive to building operations.

By contrast, coated roofs require only proactive roof maintenance, periodic inspections and minor touch-ups to keep them performing at their best. This approach keeps costs low and avoids operational headaches.

Year 20: Long-Term ROI

By year 20, most unprotected roofs face full roof replacement, a capital cost that can easily reach six figures.Buildings protected with high-quality roof coatings, however, are often still under warranty and performing reliably. That means avoiding massive replacement costs while continuing to save on energy, maintenance, and asset depreciation.

“The goal isn’t just to reflect the sun, it’s to build a resilient, energy-efficient roof that performs for decades.” – Rick Dodaj, Founder of Silicoat Roofing

The right UV resistant roof coating does more than block UV rays. It enhances your building’s long-term performance, stabilizes operating costs, and reduces the risk of unexpected repairs. By investing now, you’re securing a roof system that delivers reliability, savings, and peace of mind for years to come.

Ready to Protect and Future-Proof Your Roof?

Sun damage doesn’t just hurt your roof it hits your budget. Proactive planning today prevents costly repairs, rising energy bills, and premature roof replacements tomorrow. Whether you manage a warehouse, medical facility, or data center, our UV resistant coatings provide a scalable, long-term solution designed to meet your building’s unique needs.

At Silicoat Roofing, we’re more than contractors, we’re your strategic partner. From expert inspections to tailored material plans and seamless application, our team helps you make informed, future-focused decisions that protect what matters most.

Contact us today and get a custom plan to protect your building for decades to come.

About the Author

Rick Dodaj is the founder and CEO of Silicoat Roofing, specializing in commercial roofing solutions that protect businesses and their investments. With extensive experience in commercial roofing, Rick leads a team dedicated to providing cost-effective, long-lasting roofing solutions. Connect with him on LinkedIn to learn more about commercial roof maintenance and protection strategies.

Previous Post

Previous Post Next Post

Next Post